HEATSINKS > Air-Cooling Heatsinks > Types of Heatsinks > SERIES K---N

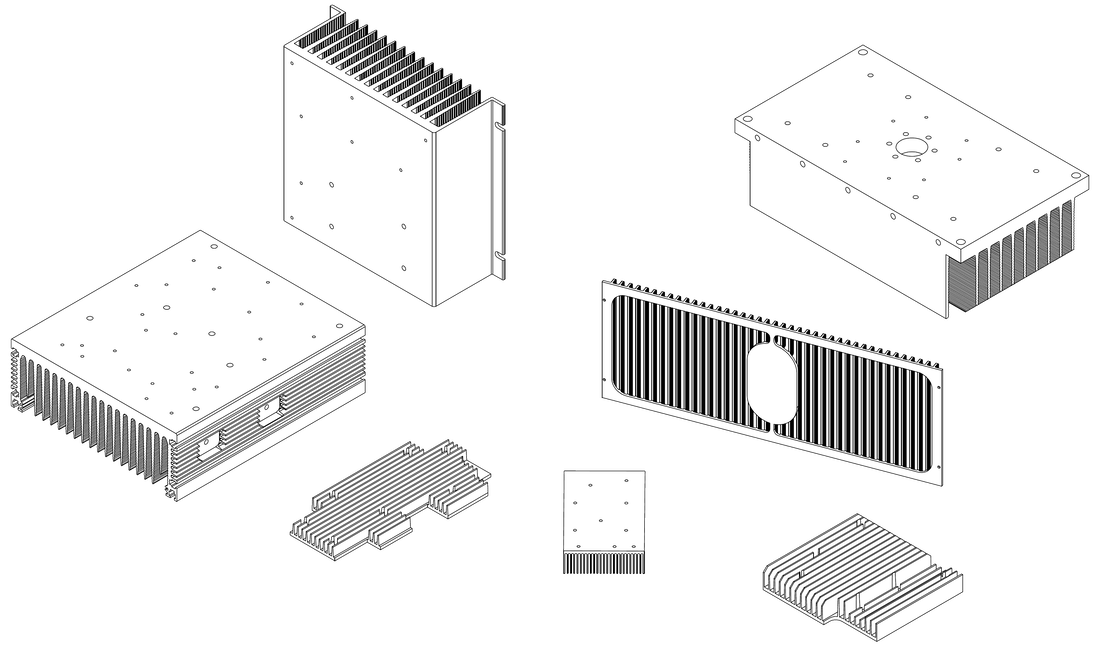

SERIES K---N

The current dissipation requirements are in focus most designers of power electronics' and push them to select heatsinks with more and more bigger dimensions. But profiles made by extrusion have dimensional limits. To decide this problem necessary to use welded extrusion heatsinks, which gives possibility to much increase of heatsinks' width.

There has been introduced in this catalogue a wide range of large welded profiles.

Recently, in order to reduce costs, production lead time and to grant the quality of the manufacturing process, it was started a new welding line completely automatic and computerized.

The welded profiles have mechanical and aesthetic features similar to the full profiles. In case of anodic oxidation welded area will have a slightly different tone color from the rest of the piece.

We are able to make on these pieces all machining as well as on full profiles.

New profiles can be designed to meet specific customers request depending on quantities requested.

All profiles of this series are stored in bars with length between 3 and 5 meters depending to the model and relative linear weight.

We are able to provide this series including all machining and any surface treatments.

To open datasheet and to select preferred for your needs K---N profile necessary:

ATTENTION:

Some cells of table are filled with light blue color. This means heatsinks in these cells have an excellent parameters not only at natural ventilation, but as well at forced ventilation. The application of high efficiency modular profiles in forced ventilation opened the way to electronic designer to exploit in the best possible conditions of new components based on modules with very high concentration of heat injection on the heatsinks with minimum possible dimensions.

For quotations please provide the following information:

1 - Profile and relevant length (Example: KEN500/400 – Specifies the profile KEN500 cut to 400mm).

2 - Quantity of batch production.

3 - Any machining, to perform better if accompanied by a file containing a technical drawing in pdf, dwg, dxf format. Dwg and dxf formats can be imported directly into our system CAD-CAM allowing a shorter time. Please provide drawing always where dimensions have not been forced.

4 - Specify any surface treatments such anodization including color, alodyne, etc...

Our commercial and technical offices are at your disposal for any clarification.

There has been introduced in this catalogue a wide range of large welded profiles.

Recently, in order to reduce costs, production lead time and to grant the quality of the manufacturing process, it was started a new welding line completely automatic and computerized.

The welded profiles have mechanical and aesthetic features similar to the full profiles. In case of anodic oxidation welded area will have a slightly different tone color from the rest of the piece.

We are able to make on these pieces all machining as well as on full profiles.

New profiles can be designed to meet specific customers request depending on quantities requested.

All profiles of this series are stored in bars with length between 3 and 5 meters depending to the model and relative linear weight.

We are able to provide this series including all machining and any surface treatments.

To open datasheet and to select preferred for your needs K---N profile necessary:

- 1) To click on HEATSINK SELECTION button.

- 2) To select preferred for you profile among different variants of heatsinks with different configuration and heatsink's main dimensions, presented into corresponding cells in opening tables.

- 3) To click on corresponding cell where interested for you heatsink is presented. At that datasheet with complete technical information for selected heatsink will be open in separate window.

- 4) To save datasheet on your computer and to use profile code in your request.

ATTENTION:

Some cells of table are filled with light blue color. This means heatsinks in these cells have an excellent parameters not only at natural ventilation, but as well at forced ventilation. The application of high efficiency modular profiles in forced ventilation opened the way to electronic designer to exploit in the best possible conditions of new components based on modules with very high concentration of heat injection on the heatsinks with minimum possible dimensions.

For quotations please provide the following information:

1 - Profile and relevant length (Example: KEN500/400 – Specifies the profile KEN500 cut to 400mm).

2 - Quantity of batch production.

3 - Any machining, to perform better if accompanied by a file containing a technical drawing in pdf, dwg, dxf format. Dwg and dxf formats can be imported directly into our system CAD-CAM allowing a shorter time. Please provide drawing always where dimensions have not been forced.

4 - Specify any surface treatments such anodization including color, alodyne, etc...

Our commercial and technical offices are at your disposal for any clarification.